Engine Oils

What does Engine Oil actually do?

Your engine oil performs many functions. It stops all the metal surfaces in your engine from grinding together and tearing themselves apart from friction, and it transfers heat away from the combustion cycle. Engine oil must also be able to hold in suspension all the nasty by-products of combustion like silica (silicon oxide) and acids. Finally, engine oil minimises the exposure to oxygen and thus oxidation at higher temperatures. It does all of these things under tremendous heat and pressure.

How do I read the '5W40' Type Number?

As oils heat up, they generally get thinner. Single grade oils get too thin when hot for most modern engines which is where multigrade oil comes in. The idea is simple - use science and physics to prevent the base oil from getting too thin when it gets hot. The number before the 'W' is the 'cold' viscosity rating of the oil, and the number after the 'W' is the 'hot' viscosity rating. So a 5W40 oil is one that behaves like a 5-rated single grade oil when cold, but doesn't thin any more than a 40-rated single grade oil when hot. The lower the 'winter' number (hence the 'W'), the easier the engine will turn over when starting in cold climates.

A quick guide to the different Grades of oil.

| Fully Synthetic | Characteristics |

|---|---|

| 0W-30 0W-40 5W-40 |

Fuel economy savings Enhances engine performance and power Ensures engine is protected from wear and deposit build-up Ensures good cold starting and quick circulation in freezing temperatures Gets to moving parts of the engine quickly |

| Semi-synthetic | Characteristics |

| 5W-30 10W-40 15W-40 |

Better protection Good protection within the first 10 minutes after starting out Roughly three times better at reducing engine wear Increased oil change intervals - don't need to change it quite so often |

| Mineral | Characteristics |

| 10W-40 15W-40 |

Basic protection for a variety of engines Oil needs to be changed more often |

Viscosity and Viscosity Index(VI).

The proper viscosity is the single most important criteria of a lubricating oil. The basic performance of machinery is based on the viscosity of the lubricant. Viscosity is, if you like, the resistance to the flowability of the oil. The thicker an oil, the higher its viscosity. The chart on the right shows a rough guide to ambient temperatures vs oil viscosity performance in both multigrade (top half) and single grade (lower half) oils.

Multigrade oils work by having a polymer added to a light base oil that prevents the oil from thinning too much as it warms up. At low temperatures, the polymers are coiled up and allow the oil to flow as it's low number (W number) indicates. As the oil heats up, the polymers unwind into long chains which prevent the oil from thinning as much as it normally would. The result is that at 100°C, the oil has thinned only as much as its higher rating. Think of it like this: a 10W30 oil is a 10-weight oil that will not thin more than a 30-weight oil when it gets hot.

The viscosity index of a lubricant is an empirical formula that allows the change in viscosity in the presence of heat to be calculated. This tells the user how much the oil will thin when it is subjected to heat. The higher the viscosity index, the less an oil will thin at a specified temperature. Multi-viscosity motor oils will have a viscosity index well over 100, while single viscosity motor oils and most industrial oils will have a VI of about 100 or less.

Here's a three-line table to give you an idea where typical engine oils are used:

| Oil type | Typically used in.... |

|---|---|

| 5W-30 | Cooler climates, like Sweden or Canada |

| 10W-40 | Temperate climates, like England |

| 15W-50 | Hot climates, like Italy, Spain, Egypt |

Why And When To Change Your Oil?

Why change your engine oil?

Engine oil is not only designed to protect your engine from wear, it also cools the internal engine parts.

Engine oil is not only designed to protect your engine from wear, it also cools the internal engine parts.

To do so, the oil gets exposed to very high thermal and mechanical stress that makes the oil lose its physical and chemical properties.

The oil is also designed to clean your engine from inside and protect it against the acid resulting from the burning of the fuel; hence it gets polluted with different types of external and internal elements.

To ensure proper lubrication all the time, your engine oil needs to be clean and non-deteriorated lubricant i.e. with no change in its chemical and physical properties.

Changing the oil will ensure to drain all the external and the internal contaminations and that your engine is being served by a non deteriorated lubricant.

When to change Oil?

Oil drain interval depends on many factors: the engine design, the driving style, the age of the engine age, the engine mileage, the ambient conditions, the lubricant used etc.Hence selecting the oil drain interval is always linked to the original car manufacturer’s recommendation and the type of lubricant you are using.

Engine Layouts

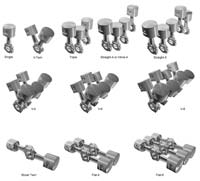

Here are some illustrations of the most common types of cylinder layout you'll find in engines today. Singles are typically used in motorbikes, snowblowers, chainsaws etc. V-twins are also found in motorbikes. The triple is almost unique to Triumph motorbikes where they call it the Speed Triple, or the 675. Inline-fours are the mainstay of car engines, as well as being found in some motorbikes too such as the BMW K1200S. Inline fives used to be used a lot in Audis but have found a new home in current Volvos. The V5 is something you'll find in some VWs. The V6 has the benefits of being smoother than an inline-four but without the fuel economy issues of a V8. Boxer engines are found in BMW motorbikes (twins) and Porsches and Subarus (fours and sixes). You had no idea, did you?.

Here are some illustrations of the most common types of cylinder layout you'll find in engines today. Singles are typically used in motorbikes, snowblowers, chainsaws etc. V-twins are also found in motorbikes. The triple is almost unique to Triumph motorbikes where they call it the Speed Triple, or the 675. Inline-fours are the mainstay of car engines, as well as being found in some motorbikes too such as the BMW K1200S. Inline fives used to be used a lot in Audis but have found a new home in current Volvos. The V5 is something you'll find in some VWs. The V6 has the benefits of being smoother than an inline-four but without the fuel economy issues of a V8. Boxer engines are found in BMW motorbikes (twins) and Porsches and Subarus (fours and sixes). You had no idea, did you?.

The Difference between 4 Stroke and 2 Stroke Engines

Almost every car sold today has a 4 stroke engine. So do a lot of motorbikes, lawnmowers, snowblowers and other mechanical equipment. But there are still a lot of 2 stroke engines about in smaller motorbikes, smaller lawnmowers, leaf-blowers, snowblowers and such. The difference between the two engine types is the number of times the piston moves up and down in the cylinder for a single combustion cycle. A combustion cycle is the entire process of sucking fuel and air into the piston, igniting it and expelling the exhaust.

Almost every car sold today has a 4 stroke engine. So do a lot of motorbikes, lawnmowers, snowblowers and other mechanical equipment. But there are still a lot of 2 stroke engines about in smaller motorbikes, smaller lawnmowers, leaf-blowers, snowblowers and such. The difference between the two engine types is the number of times the piston moves up and down in the cylinder for a single combustion cycle. A combustion cycle is the entire process of sucking fuel and air into the piston, igniting it and expelling the exhaust.

How 2 stroke Engines Work

A 2 stroke engine is different from a 4 stroke engine in two basic ways. First, the combustion cycle is completed within a single piston stroke as oppose to two piston strokes, and second, the lubricating oil for the engine is mixed in with the petrol or fuel. In some cases, such as lawnmowers, you are expected to pre-mix the oil and petrol yourself in a container, then pour it into the fuel tank. In other cases, such as small motorbikes, the bike has a secondary oil tank that you fill with 2 stroke oil and then the engine has a small pump which mixes the oil and petrol together for you.

The simplicity of a 2 stroke engine lies in the reed valve and the design of the piston itself. The picture on the right shows a 4 stroke piston (left) and a 2 stroke piston (right). The 2 stroke piston is generally taller than the 4 stroke version, and it has two slots cut into one side of it. These slots, combined with the reed valve, are what make a 2 stroke engine work the way it does. The following animation shows a 2 stroke combustion cycle. As the piston (red) reaches the top of its stroke, the spark plug ignites the fuel-air-oil mixture. The piston begins to retreat. As it does, the slots cut into the piston on the right begin to align with the bypass port in the cylinder wall (the green oblong on the right). The receding piston pressurises the crank case which forces the reed or flapper valve (purple in this animation) to close, and at the same time forces the fuel-air-oil mixture already in the crankcase out through the piston slots and into the bypass port. This effectively routes the mixture up the side of the cylinder and squirts it into the combustion chamber above the piston, forcing the exhaust gas to expel through the green exhaust port on the left. Once the piston begins to advance again, it generates a vacuum in the crank case. The reed or flapper valve is sucked open and a fresh charge of fuel-air-oil mix is sucked into the crank case. When the piston reaches the top of its travel, the spark plug ignites the mixture and the cycle begins again.

For the same cylinder capacity, 2 stroke engines are typically more powerful than 4 stroke versions. The downside is the pollutants in the exhaust; because oil is mixed with the petrol, every 2 stroke engine expels burned oil with the exhaust. 2 stroke oils are typically designed to burn cleaner than their 4 stroke counterparts, but nevertheless, the 2 stroke engine can be a smoky beast. If, like me, you grew up somewhere in Europe where scooters were all the rage for teenagers, then the mere smell of 2 stroke exhaust can bring back fond memories. The other disadvantage of 2 stroke engines is that they are noisy compared to 4 stroke engines. Typically the noise is described as "buzzy".

How 4 stroke Engines Work

4 stroke engines are typically much larger capacity than 2 stroke ones, and have a lot more complexity to them. Rather than relying on the simple mechanical concept of reed valves, 4 stroke engines typically have valves at the top of the combustion chamber. The simplest type has one intake and one exhaust valve. More complex engines have two of one and one of the other, or two of each. So when you see "16v" on the badge on the back of a car, it means it's a 4-cylinder engine with 4 valves per cylinder - two intake and two exhaust - thus 16 valves, or "16v". The valves are opened and closed by a rotating camshaft at the top of the engine. The camshaft is driven by either gears directly from the crank, or more commonly by a timing belt. The following animation shows a 4 stroke combustion cycle. As the piston (red) retreats on the first stroke, the intake valve (left green valve) is opened and the fuel-air mixture is sucked into the combustion chamber. The valve closes as the piston bottoms out. As the piston begins to advance, it compresses the fuel-air mix. As it reaches the top of its stroke, the spark plug ignites the fuel-air mix and it burns. The expanding gasses force the piston back down on its second stroke. At the bottom of this stroke, the exhaust valve (right green valve) opens, and as the piston advances for a second time, it forces the spent gasses out of the exhaust port. As the piston begins to retreat again, the cycle starts over, sucking a fresh charge of fuel-air mix into the combustion chamber.

Because of the nature of 4 stroke engines, you won't often find a single-cylinder 4 stroke engine. They do exist in some off-road motorbikes but they have such a thump-thump-thump motion to them that they require some large balancing shafts or counterweights on the crank to try to make the ride smoother. They also take a little longer to start from cold because you need to crank the single piston at least twice before a combustion cycle can start. Any more than one piston and the engine gets a lot smoother, starts better, and is nowhere near as thumpy. That's one of the advantages of V-6 and V-8 engines. Apart from the increased capacity, more cylinders typically means a smoother engine because it will be more in balance. Geek trivia: Mercedes-Benz needed to increase the performance of their diesel passenger cars back in the 70's as their market share in the US was increasing. As professionals with big V-8 luxury cars were trading them in for 2.4l diesels, the demand for performance had to be addressed. Mercedes did not want to retool their 114/115 series chassis and there wasn't enough room in the engine bay for a six cylinder diesel. There was, however, room for a straight-5. Benz engineers just hung another cylinder on the back of the 4 cyl block and presto! The five cylinder engine was born. This engine acquired a lot of status among the high line car owners. When Audi introduced the C2 series cars (the 5000 in America, the 100 in Europe) in 1976, they offered a 5-cylinder petrol engine too. It was basically a 1.8 litre 4-cylinder engine with an extra cylinder. That took it up to 2.0 litres but the fifth piston made such an enormous difference to the smoothness of the engine that it was often mistaken for a V6 or V8. Why only 5 cylinders instead of going for a V6? Partly for the same rationale as Mercedes (and it was a really tight fit) but primarily because Benz had made the straight-5 configuration fashionable. A straight-5 was also more fuel-efficient than a V6. It's also worth pointing out that nowadays, both Audi and VW have V5 engines with three cylinders in one bank and two in the other. Same smoothness, better gas-mileage.

Fuel Efficiency

Fuel economy Concept

More kilometers, more economy.

More kilometers, more economy.

More environmentally friendly, lower CO2 emissions.

More protection, less wear.

Fuel Economy range of lubricants should meet the requirements of business and private users wishing to improve the performance and lifespan of their vehicles while noticeably reducing fuel consumption.

Calculate the potential fuel savings for your passenger car.

A Fuel Economy lubricants enable a reduction in polluting emissions per km/mile, they optimize the efficiency of vehicle post-treatment systems and prolong engine life due to engine cleanliness and anti-wear protection.

An approved lubricant

The ACEA (European Automobile Manufacturers' Association) rdefines a Fuel Economy lubricant as a lubricant in compliance with ACEA C1, C2, A5/B5, A1/B1 standards. For this, it must successfully undergo an engine test (Test M111FE) in which the fuel economy is measured and established by comparison with the use of the reference mineral oil. The ACEA C1 standard sets this value at 3%, the ACEA C2, A5/B5, A1/B1 standards set this value at 2.5%.

What if we all used Fuel Economy Lubricants?

For an average distance covered of 14,000 km, petrol or diesel, the estimation is 160,000 tons of CO2 not emitted into the atmosphere by comparison with the use of a mineral oil (Results obtained compared to a mineral oil on petrol & diesel engines of 2.9 million PSA Peugeot Citroën vehicles for an average distance of 14,000 km). These 160,000 tons represent the equivalent CO2 absorbed by 2,000 acres of French forests or 1,450 acres of Brazilian forest (FAO source: 75 tons of carbon in the biomass per acre of French forest, 103 tonnes for the Brazilian forest).