Engine Oil Formulation..

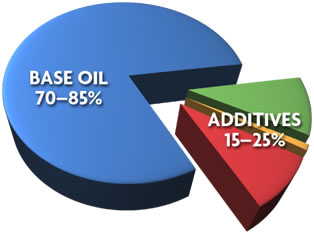

Engine oil is comprised of two basic components—base oils and additives. The base oils constitute 70 to 85 percent of the total, while additives round out the remaining 15 to 25 percent.

These additives, known collectively as the Performance Additive Package, are comprised of dispersants, detergents, anti-wear additives, friction modifiers, antioxidants, anti-foam additives and corrosion inhibitors. In addition to the Performance Additive Package, motor oil additives also include a viscosity index improver and a pour-point depressant.

Dispersants:

A dispersant helps keep sludge from forming on internal engine parts by suspending contaminants in the oil until they can be safely removed at the next oil change.

Detergents:

Detergents operate on high-temperature surfaces, such as the piston-ring area and the piston under-crown, helping to prevent deposits. These detergents get consumed over the life of your oil change.

Anti-Wear Agents:

Anti-wear agents form a protective coating on metal surfaces. They also provide an antioxidant boost. Anti-wear agents operate under high temperatures and high load conditions, particularly protecting cams, lifters, piston rings and cylinder walls. Anti-wear agents cloak these surfaces in a “sacrificial layer” or film, which is consumed in the protective process. Without this “sacrificial layer,” metal-to-metal contact would occur. Like detergents, anti-wear agents also get consumed over the life of your oil change. Another reason you should always change your oil at recommended intervals.

Friction Modifiers:

These do what you think; they reduce friction under high loads and high temperatures, helping to maintain peak efficiency and fuel economy. The effectiveness of these additives diminishes over time as the oil ages.

Antioxidants:

Oxidation results from exposure of the oil to oxygen at high temperatures. It’s not a good thing. The results of such exposure can accelerate the aging of the oil contributing to oil thickening, sludge and deposits. Antioxidants help slow oxidation in the oil to help keep engines running clean.

Anti-Foam Additives:

Foam-causing air bubbles create a variety of problems in oil. They make oil harder to pump to vital engine parts, reduce the oil’s lubrication effectiveness, and inhibit the oil’s ability to help keep the engine cool. A foamed-up oil can result in serious engine damage. An anti-foam additive helps prevent these problems, specifically at high temperatures.

Rust and Corrosion Inhibitors:

It might sound strange, but internal engine parts can be subject to rust and corrosion. Rust and corrosion inhibitors coat metal surfaces, protecting against these hazards.

Viscosity Index Improvers:

The Viscosity index measures an oil’s ability to resist changes in viscosity as temperature changes. Viscosity index improvers utilize polymer additives to help maintain oil viscosity over a wide range of temperatures. The use of Viscosity index improvers allows the formulation of multi-grade engine oils, such as 10W-30 and SAE 10W-30.

Pour-Point Depressants:

These are used in multi-grade oils to provide good oil flow at low temperatures. Flow is important in cold engines as oils that are difficult to pump through the engine require additional energy to circulate—like a clogged artery. This results in added stress on the engine and decreased efficiency.